DOWNLOAD DEZURIK'S VALVE SOLUTIONS GUIDE FOR PUMP STATIONS

DeZURIK’s Valve Solutions for Pump Stations bulletin highlights DeZURIK/APCO/HILTON and Willamette capabilities in pump station applications. DeZURIK has been recognized worldwide as the industry leaders in providing design assistance to engineers and owners by recommending valve solutions that provide superior performance and value. The new bulletin includes photos of pump station installations demonstrating the company’s extensive experience and expertise. Included in the bulletin is pertinent information on valves commonly used in pump station applications: description, services, size range, pressure rating, average K factors and a relative price scaled for $ for the lowest cost to $$$$ for the premium valve styles. In addition, the bulletin highlights the value-added service the company provides such as the Surge Investigation and Valve Suggestions Report or the “Valve Solutions” engineering seminars.

Valve Solution Guide for Pump Stations

Valve Solution Guide for Pump Stations

HYdraulics based pump station valve solutions

Challenge:

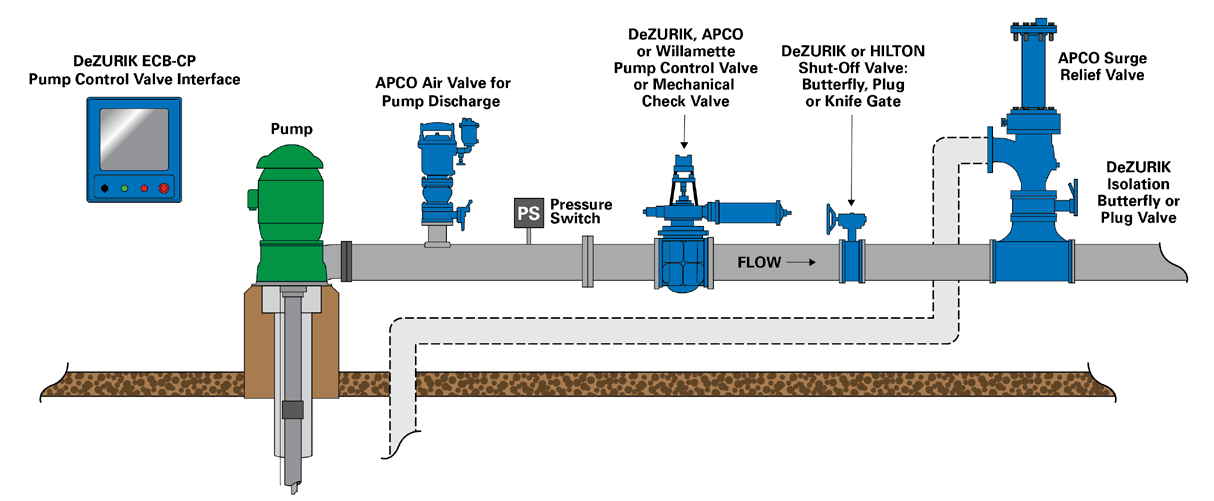

Pump station valve selection can present a challenge to the Engineer and Owner. Common considerations include preventing the damaging consequences of surge pressure transients (water hammer) related safety issues, pipeline breaks, fitting failures, cross connection, flooding and water loss. Additional concerns may include minimizing check valve slam, elimination of air pockets and vacuum conditions, surge relief valve necessity and size, pump control valve considerations and options, valve operating speeds, reducing pumping energy costs and dependable isolation valve service.

Solution Assistance:

DeZURIK offers applications assistance and valve solutions specifically for pump station design challenges. DeZURIK’s broad range of valves under the DeZURIK/APCO/Hilton and Willamette brands combined with in-depth expertise of our technical staff uniquely positions DeZURIK to study pumping systems and to provide options for practical, cost effective check valves, pump control valves, surge relief valves, air valves and isolation valve solutions.

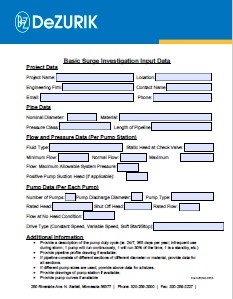

To get started, simply complete the basic surge investigation input data form and return to DeZURIK/APCO/HILTON at info@dezurik.com or your representative for review.

To get started, simply complete the basic surge investigation input data form and return to DeZURIK/APCO/HILTON at info@dezurik.com or your representative for review.

Find your local DeZURIK representative

"DeZURIK Valve Solutions" Engineering Seminars

DeZURIK Valve Solutions seminars are designed for Consultants, Municipal Engineers and Operations Managers involved with design and valve selection for any type of fluid handling system. Presented by DeZURIK personnel with in-depth practical experience, these half-day seminars include surge and slam theory and show how using the right valves and controls will make your systems work better. These no cost seminars feature pump control valves, check valves, surge relief valves, isolation valves, air valves and the pump/valve interface panel. A four (4) hour certificate of training will be presented to all participants. Contact your local DeZURIK representative to schedule a seminar in your area today.

Pump station application data:

Early in the pump station design process, DeZURIK collects information from the Engineer in order to determine the technical parameters of the particular pumping application and to develop an understanding of the customer requirements. DeZURIK’s Basic Surge Investigation Input Data Form can be used to efficiently provide the pertinent information.

Surge investigation, valve suggestion report:

The potential for surge pressure transients (water hammer) is examined utilizing governing fluid mechanics equations. A report will be provided that includes: the maximum surge pressure potential, the surge period, line velocity, surge wave speed, pipeline constant, and total system head potential during a surge event. Investigation of these results and the information provided enables DeZURIK to include in the report suggestions for applying check valves, pump control valves, surge relief valves, and air valves to minimize surge pressure. In addition, the check valve or pump control valve suggestion can be discussed. The potential for check valve slam can be addressed and valve solution options provided. Pump Control Valve Actuation options can also be evaluated. The need for surge relief valves can be investigated and surge relief valve sizing suggestions will be provided if applicable. A study can also be provided that takes into account pumping costs (head loss), valve budgetary pricing and relative maintenance costs of different valve types to arrive at valves that provide the lowest cost of ownership of the project life. Alternatively, if there is a preferred valve design, DeZURIK is available to confirm its suitability for a particular project. Suggested specifications for the valves selected for use on the project by the Engineer and tailored to the particular application will then be provided.

PRODUCTS FOR PUMP STATIONS

DeZURIK manufactures a wide variety of valve styles used in Pump Stations, including SmartCHECK Pump Control Valves, Plug Valves, Butterfly Valves, Butterfly Valves, Knife Gate Valves, Air Valves, Surge Relief Valves, Ball Valves and Cone Valves. To see details on each valve style, choose one of the following product categories: