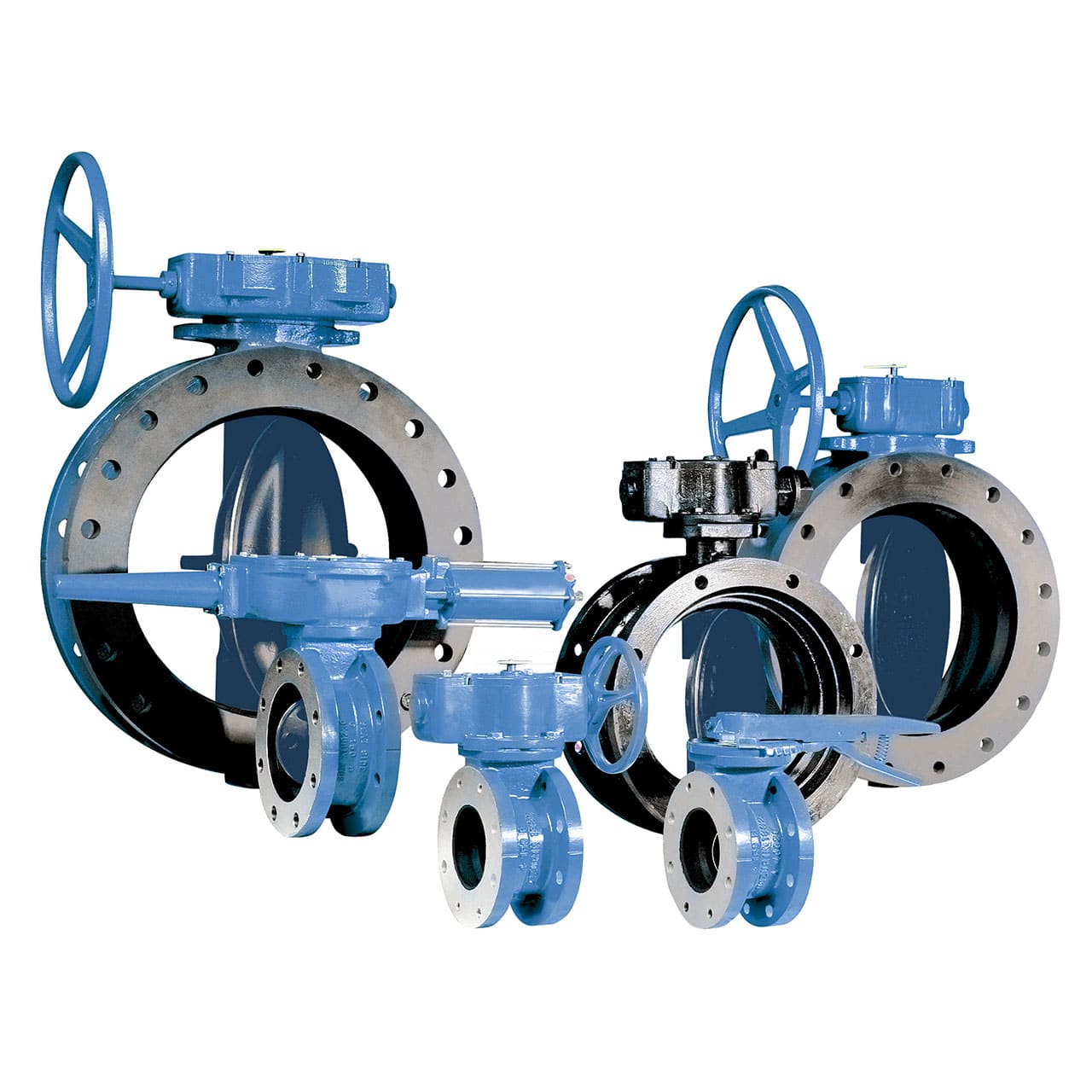

Installation Guidelines for AWWA Butterfly Valves

In this comprehensive AWWA Butterfly Valve Installation Guide, you will learn essential factors that influence butterfly valve performance—many of which are often overlooked during system design and installation. Installing AWWA (American Water Works Association) butterfly valves in pumping, distribution, or plant piping systems requires careful attention to a variety of engineering considerations to ensure optimal performance, reliability, and longevity.

Key topics include flow direction, which directly impacts dynamic torque and actuator sizing. Improper orientation—especially with offset seated valves—can lead to excessive torque demands, actuator failure, and reduced system efficiency. The article also emphasizes the importance of mitigating upstream disturbances caused by nearby pumps, elbows, or valves, which can create turbulent, unbalanced flow and cause disc flutter, increased wear, and premature failure.

Valve shaft orientation—horizontal vs. vertical—plays a critical role in minimizing bearing wear and preventing the buildup of debris, especially in buried or raw water applications. Additionally, correct disc closure direction can reduce the risk of debris interference and enhance self-cleaning during operation.

The article also discusses critical installation best practices, including ensuring adequate disc swing clearance, avoiding chemical injection points near valves to prevent seat degradation, and controlling fluid hammer through proper actuator speed or manual operation. Detailed startup and maintenance guidelines highlight the importance of correct alignment, bolt torque, and leak inspection.

This article is a valuable guide for engineers, contractors, and operators looking to ensure efficient, trouble-free AWWA butterfly valve installations. Understanding these foundational principles can significantly improve valve performance and reduce costly downtime in municipal and industrial systems.

Explore the full guide to avoid common mistakes and extend valve lifespan.