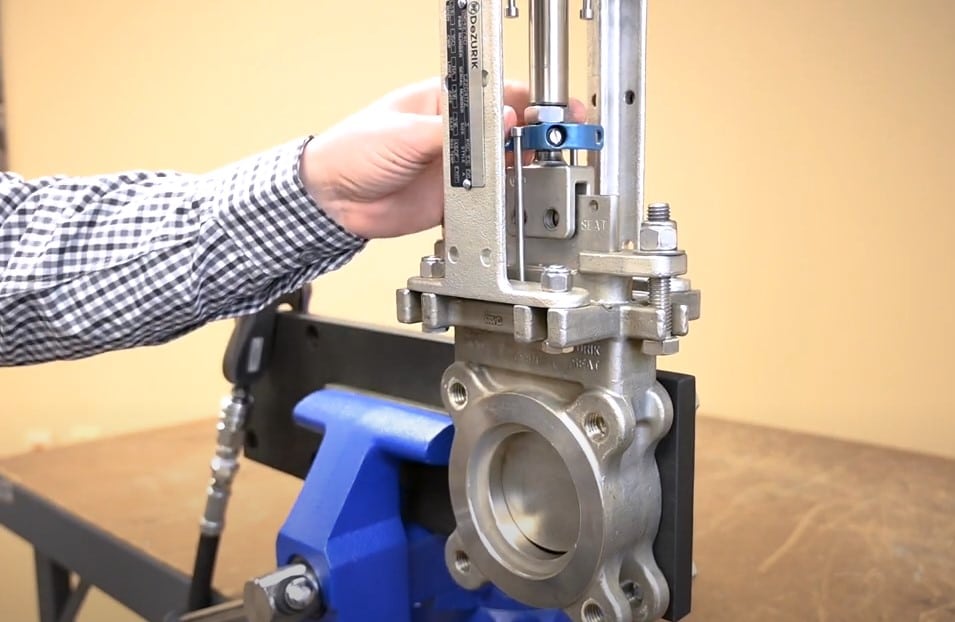

How to Adjust the Stroke on a Knife Gate Valve Cylinder Actuator

Learn how to Adjust the Stroke on Knife Gate Valve Cylinder Actuator to ensure reliable operation and extend the life of your valve system. In this detailed tutorial, we guide you through the process of testing and adjusting the cylinder stroke, a step typically necessary after maintenance work on the valve or actuator. Proper stroke adjustment is essential to ensure the valve gate closes fully and opens far enough to clear the port opening, helping you avoid costly issues like leakage, premature wear, and operational failure.

The video demonstrates:

- Setting the Valve Closure Distance: Learn how to fine-tune the cylinder actuator to achieve a complete seal.

- Setting the Valve Open Distance: See how to adjust the actuator to open the gate just enough to clear the port, ensuring the gate stays in contact with the seat and avoids flow path obstruction that can cause seat or gate damage.

Correctly adjusting both open and close limits not only prevents operational issues but also maximizes valve longevity and minimizes unplanned downtime. This easy-to-follow guide makes the adjustment process straightforward, helping maintenance crews keep DeZURIK Knife Gate Valves operating at peak performance.

DeZURIK manufactures a wide variety of both cast and fabricated Knife Gate Valves that are used in isolation/on-off applications to handle a wide variety of media including liquids, paper stock, slurries, chemicals, and dry materials. Numerous designs with special construction or for special services are also available.

For expert support, contact your local DeZURIK representative today. Watch the video now to learn how to adjust the stroke on knife gate valve cylinder actuators like a pro!