What Valve Considerations Are Commonly Overlooked During Specification and Selection?

Valve specification and selection are critical steps in every new system design. While engineers typically focus on defined operating conditions—such as service media, pressure, temperature, and piping layout—there are several often overlooked or undefined considerations that can significantly impact valve performance and system reliability over time.

Why Do Valve Requirements Change Over Time?

System requirements frequently evolve due to:

-

Capacity increases

-

Process or product changes

-

Operational adjustments

-

Facility expansions

These changes can introduce new operating scenarios that were not accounted for in the original valve selection. When this happens, system problems may arise that require a broader analysis beyond the original design criteria.

What Are “Undefined” Valve Expectations?

In addition to normal operating conditions, valves are often exposed to infrequent but severe conditions that may not be clearly defined during specification, including:

-

Startup and shutdown events

-

Upset or abnormal operating conditions

-

Emergency scenarios

These situations can be more demanding than normal service conditions and may exceed the valve’s original design intent if not considered upfront.

What Performance Expectations Are Often Missing?

Other valve expectations that may be undefined or underestimated during selection include:

-

Shutoff capability and leakage performance

-

Control accuracy and response characteristics

-

Reliability during transient conditions

-

Long-term suitability for future facility plans

These expectations differ depending on whether the valve is used for control or isolation, and each application requires its own evaluation criteria.

What Valve Selection Factors Are Most Often Overlooked?

The following categories represent commonly overlooked or undefined expectations that should be evaluated during valve specification and selection to ensure reliable long-term performance:

-

Non-normal operating conditions

-

Startup, shutdown, and emergency performance

-

Control vs. isolation functional requirements

-

Future system changes and expansion plans

Addressing these factors early can help reduce operational issues, extend valve life, and improve overall system performance.

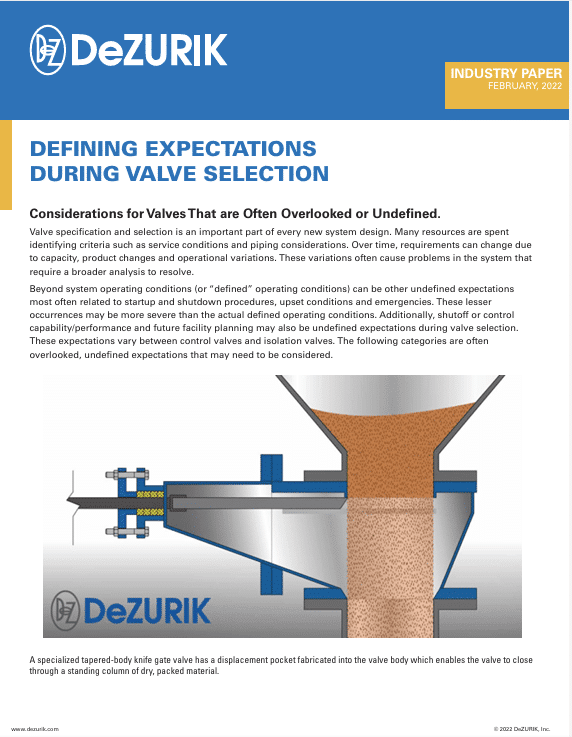

To learn more, download this informative white paper “Defining Expectations During Valve Selection“