Prevent Check Valve Slam with Bottom Mounted Buffer

Prevent Check Valve Slam in your piping system with the right solutions! Valve slam is a common issue that can cause noise, valve damage, pipeline shaking, and even surge. While it’s often caused by rapid flow reversal, the good news is that valve slam can be avoided with the proper closure control devices. In many cases, a lever-and-weight or lever-and-spring mechanism can help close the valve before flow reversal occurs. However, in certain applications—like high static head, vertical pipe runs, or systems with hydro pneumatic surge tanks—valve slam may still occur.

APCO Swing Check Valves are used to prevent the back flow of fluid by closing before flow reversal, thereby preventing slam and water hammer. APCO Swing Check Valves have been successfully installed in clean and dirty applications including sewage treatment, water treatment, water distribution, industrial water and wastewater services. The industrial swing check valve design meets or exceeds the current revision of AWWA standard C508.

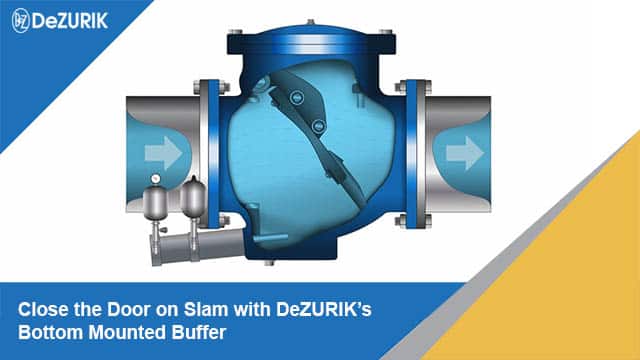

For these challenging scenarios, the APCO CVS-6000 swing check valve, equipped with a bottom-mounted buffer, provides a reliable solution. This innovative valve and closure device controls the last 10% of disc travel by decelerating the disc before it closes, effectively mitigating check valve slam. This reduces the risk of damage, surge, and unnecessary noise, ensuring smoother and more efficient system operation.

In this video, you’ll learn how the APCO CVS-6000 swing check valve with bottom-mounted buffer technology helps protect your system from the adverse effects of valve slam. This solution is ideal for applications that involve high-pressure environments, rapid flow reversals, and challenging pipe configurations.

To learn more about how the APCO Check Valves can prevent backflow and valve slam, watch the video and contact your local DeZURIK representative for further technical support and solutions to improve your system’s reliability.