Guidelines

Elastomer Selection Guidelines

DeZURIK Elastomer Selection Guidelines

The DeZURIK Elastomer Selection Guide is intended to be of assistance in the selection of the most suitable elastomer for various chemical services. This guide should only be used as a starting point in the selection process. There are many factors that affect an elastomer’s suitability that cannot be adequately expressed in chart form.

Factors Affecting Elastomer Selection

When selecting the most suitable elastomer for a particular application, many factors must be considered that can influence the service of the elastomer. These factors can include the type of chemical, temperature, concentration, abrasiveness, velocity, time of exposure and seating forces. These factors can lead to two basic types of failure: chemical deterioration and mechanical damage. When elastomer failure does occur, it will often be a combination of these two types of failure.

Chemical deterioration can occur by an actual chemical reaction between the media and the elastomer, or by an absorption of the media into the elastomer. Chemical deterioration leads to a decrease in the tensile strength and often to a swelling of the elastomer. The amount of chemical deterioration depends upon and generally increases with increasing temperature and concentration of the service. Chemical absorption can lead to a weakening of the bond with a resulting bond failure and a separating of the elastomer from the metal.

Although elastomers can be damaged by mechanical means only, the mechanical damage often occurs because of chemical deterioration. In a deteriorated condition, the weakened elastomer is more susceptible to damage from the flowing media especially if the media are highly abrasive and flowing at a high velocity. If a deteriorated elastomer has also swelled, the lost strength coupled with the resulting interference between the seating surfaces can lead to mechanical damage when the valve is closed.

An elastomer facing or lining, when in good physical condition, will often give abrasion resistance superior to metal. The actual size, shape, and hardness of the particles and their velocity are the determining factors in how well a particular elastomer resists mechanical damage from the media. Hard, sharp objects, including those foreign to the normal media, may cut or gouge the elastomer.

Seating forces higher than those recommended can put excessive strain on elastomer facings. Excessive strain on the elastomer will lead to shorter facing life especially if any chemical deterioration has occurred. Excessive seating forces may also lead to compression set of the elastomer. Compression set is a permanent deformation that remains in the elastomer after a compression force has been removed; this compression force occurs when the valve is closed. The area of the elastomer that has compression set is not only permanently deformed but is also less resilient than normal and may not offer the same shut-off. The possibility of compression set occurring increases with increasing temperature, compression force, and the length of time that the force is applied, and dependent upon the type of the elastomer.

Economics is not as important a factor in elastomer selection as it is in metal selection. Many of the available elastomers are the same price and the extra cost for others is often small when compared to the price of the complete valve.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Metal Selection Guidelines

DeZURIK Metal Selection Guidelines

Economics play an important role in the selection of the proper valve material. Since the more corrosion resistant materials such as stainless steel, Monel, etc., are also higher in cost, such considerations as increased valve life, cost difference, difficulty caused by valve failure and ease of replacement must be made in determining if the higher cost material is justified.

The pressure rating of the valve may also be a limiting factor in the valve material selection since the pressure rating differs with valve size and valve material. Carbon steel, stainless steel, and the more noble alloys have a higher pressure rating than bronze and bronze has a higher pressure rating than cast iron and Ni-Resist.

Types of Corrosion

There are many types of corrosion and each has a different effect on various metals. Two of the most important types that are frequently encountered in valves are general corrosion and pitting corrosion.

General corrosion attacks the metal uniformly, over the entire surface, forming oxides that go into solution or adhere to the metal surface. If adherence occurs, these oxides often act as a protective coating that retards further corrosion.

The most important factors that affect the rate of general corrosion are the temperature and concentration of the corrosive media. For all practical purposes, the rate of corrosion increases with increasing temperature. In general, the corrosiveness of a particular service also increases as its concentration increases. However, there are some services such as sulfuric acid where a lower concentration may be more corrosive than a higher concentration.

The velocity and abrasiveness of the media flowing past a metal surface also affects the rate of corrosion. A flowing media has a tendency to wear away any protective oxides that may have formed on the metal surface, thus leaving the metal more susceptible to further corrosion. As the velocity and abrasiveness of the media increases, the corrosion rate will also increase. This type of attack is often referred to as corrosion-erosion.

Pitting corrosion takes place when a protective coating of oxides is penetrated only at particular points. Once this penetration has occurred, pitting can proceed rapidly and deeply to a point of penetrating the metal. Pitting, which is most frequently found with stainless steels, is most apt to occur when the corrodents contain one of the halogens, such as chlorine.

Pitting is usually found under deposits from the corrosive media that have adhered to the metal surface, such as paper stock, due to a stagnant fluid condition. It is because of this formation that any velocity of the corrosive media may actually eliminate the possibility of this type of corrosion.

The addition of molybdenum to stainless steel will increase its resistance to pitting. Alloy 20 and 316 stainless steel, which have molybdenum, are more resistant to pitting than 304 stainless steel.

Good experience, backed up by good records of corrosion and valve life are valuable assets in the selection of the most suitable valve material. Particular characteristics of the service conditions which are not considered by the corrosion charts or recommendation guides can easily make experience the most important consideration in valve material selection.

Applications with service conditions that combine a mixture of corrosive media may result in more severe attack on the metal that any of the individual corrosive media handled separately. Selecting the correct material can only be accomplished through experience or by testing.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Elastomer / Polymer Material Data

CIIR (Chloro-Isobutene-Isoprene)

DeZURIK Elastomer Compound Description and Rating

CIIR (Chloro-Isobutene-Isoprene)

CIIR has outstanding impermeability to gases, excellent dielectric properties, good resistance to tearing, good aging properties at elevated temperatures and good chemical stability.

Mechanical Resistance Properties:

| IMPACT | GOOD |

| ABRASION | GOOD |

| TEAR | GOOD |

| CUT GROWTH | EXCELLENT |

Maximum Temperature Rating: 250°F (122°C)

Note: Not recommended for dry service on PEC and PEF Eccentric Plug Valves.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

CR (Chloroprene)

DeZURIK Elastomer Compound Description and Rating

CR (Chloroprene)

CR is resistant to gasoline, sunlight, ozone and oxidation. It is flame resistant and will not support combustion. It has good resistance to the corrosive action of chemicals and water.

Mechanical Resistance Properties:

| IMPACT | GOOD |

| ABRASION | GOOD to EXCELLENT |

| TEAR | GOOD |

| CUT GROWTH | GOOD |

Maximum Temperature Rating: 180°F (82°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

EPDM (Terpolymer of Ethylene, Propylene and a Diene)

DeZURIK Elastomer Compound Description and Rating

EPDM (Terpolymer of Ethylene, Propylene and a Diene)

EPDM is resistant to oxygen and ozone and has excellent color retention.

Mechanical Resistance Properties:

| IMPACT | GOOD |

| ABRASION | GOOD |

| TEAR | FAIR |

| CUT GROWTH | GOOD |

Maximum Temperature Rating:

- All Products except as noted below 250°F (121°C)

- AWWA Butterfly Valve 290°F (143°C)

- Air Valves, Check Valves (excluding CVS-6000/6000A/6000D), Surge Relief Valves, 300°F (150°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

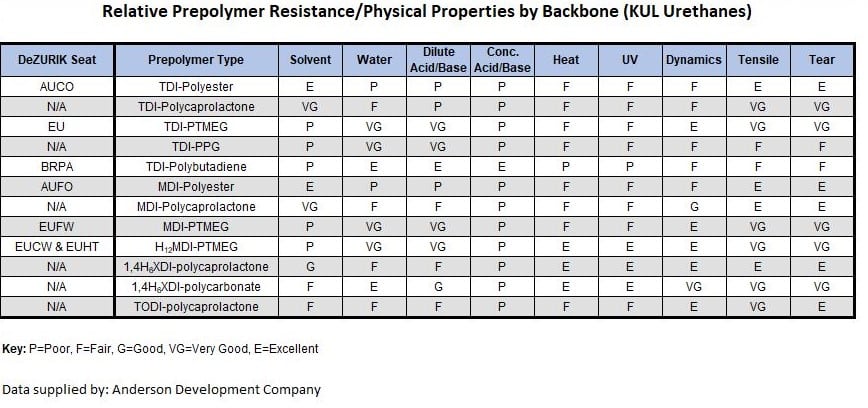

EU (Urethane)

DeZURIK Elastomer Compound Description and Rating

EU (Urethane)

Urethane is recommended for dry solids and abrasive slurries. It has excellent qualities for wear, tear and abrasion. It is resistant to oil and ozone.

Mechanical Resistance Properties:

| IMPACT | EXCELLENT |

| ABRASION | EXCELLENT |

| TEAR | EXCELLENT |

| CUT GROWTH | FAIR to EXCELLENT |

Maximum Temperature Rating: 175°F (80°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

FKM (Fluoro Rubber)

DeZURIK Elastomer Compound Description and Rating

FKM (Fluoro Rubber)

FKM has excellent resistance to oils, fuels, lubricants, most mineral acids and many aliphatic and aromatic hydrocarbons that act as solvents for other rubbers. Excellent resistance to ozone, oxygen and weathering.

Mechanical Resistance Properties:

| IMPACT | POOR to GOOD |

| ABRASION | GOOD |

| TEAR | FAIR to GOOD |

| CUT GROWTH | POOR to GOOD |

Maximum Temperature Rating:

- Eccentric Plug Valves, Air Valves, Check Valves, Surge Relief Valves, 450°F (232°C)

- Resilient Seated Butterfly Valves, KGC Knife Gate Valves 400°F (204°C)

- CRF Flapper Swing Check Valves 425°F (218°C)

- KGC-BD Knife Gate Valves and PGV Ported Gate Valves 350°F (177°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

NBR (Acrylonitrile-Butadiene)

DeZURIK Elastomer Compound Description and Rating

NBR (Acrylonitrile-Butadiene)

NBR is primarily used for applications requiring resistance to petroleum oils, gasoline, aromatic hydrocarbons, mineral and vegetable oils.

Mechanical Resistance Properties:

| IMPACT | FAIR |

| ABRASION | EXCELLENT |

| TEAR | GOOD |

| CUT GROWTH | GOOD |

Maximum Temperature Rating:

- All products except as noted below 180°F (83°C)

- Air Valves, Check Valves (excluding CVS-6000D), Surge Relief Valves 250°F (121°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

NR (Natural Rubber)

DeZURIK Elastomer Compound Description and Rating

NR (Natural Rubber)

NR provides a balance of tear strength, high resilience and tensile strength, good abrasion resistance and good flexural properties at low temperatures.

Mechanical Resistance Properties:

| IMPACT | EXCELLENT |

| ABRASION | EXCELLENT |

| TEAR | EXCELLENT |

| CUT GROWTH | EXCELLENT |

Maximum Temperature Rating: 180°F (82°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

NRH (Hard Natural Rubber)

DeZURIK Elastomer Compound Description and Rating

NRH (Hard Natural Rubber)

NRH is a special natural rubber, graphite loaded ebonite with resistance to wet or dry chlorine gas, chlorinated brine and chlorine water solutions.

Mechanical Resistance Properties:

| IMPACT | POOR to FAIR |

| ABRASION | POOR to FAIR |

| TEAR | POOR to FAIR |

| CUT GROWTH | POOR to FAIR |

Maximum Temperature Rating: 180°F (82°C)

Notes: The leak rate of a hard natural rubber lined valve is equivalent to a metal-to-metal seated valve.

Not recommended for abrasive slurry applications. Where hard natural rubber and Chloroprene (CR) are recommended for a specific service, a CR soft rubber overlay on the plug is available for tight shut-off.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

PTFE (Polytetraflouroethylene)

DeZURIK Compound Description and Rating

PTFE (Polytetraflouroethylene)

PTFE provides excellent chemical resistance to most non-abrasive fluids. It is a polymer, not an elastomer. To be used as a sealing member in a valve. Other factors such as fluid forces, elastomers, mechanical devices or a combination of these must be present to provide “elasticity” or memory to the PTFE sealing member.

Mechanical Resistance Properties:

| IMPACT | POOR to FAIR |

| ABRASION | POOR to FAIR |

| TEAR | POOR to FAIR |

| CUT GROWTH | POOR to FAIR |

Maximum Temperature Rating:

- High Performance Butterfly Valve (BHP)

- (TT) 450°F (232°C)

- (RT) 500°F (260°C)

- V-Port Ball Valve (VPB)

- (RT) 500°F (260°C)

Note: The PTFE temperature rating is dependent on pressure. Please see the appropriate bulletin for pressure-temperature ratings.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Metal Material Data – Pressure Temperature Ratings

304 Stainless Steel – ASTM A351, CF8

DeZURIK Pressure Temperature Rating Guide

304 Stainless Steel – ASTM A351, CF8

| Temperature (°F / °C) |

Pressure (psi / kPa) | ||||

|---|---|---|---|---|---|

| ASME Class | |||||

| 150 | 300 | ||||

|

-20 to 100

-30 to 40 |

275

1900 |

720

5000 |

|||

|

200

93 |

230

1600 |

600

4100 |

|||

|

300

150 |

205

1400 |

540

3700 |

|||

|

400

200 |

190

1300 |

495

3400 |

|||

|

500

260 |

170

1200 |

455

3200 |

|||

|

600

320 |

140

970 |

440

3000 |

|||

|

650

340 |

125

860 |

430

3000 |

|||

|

700

370 |

110

760 |

420

2900 |

|||

|

750

400 |

95

660 |

415

2900 |

|||

|

800

430 |

80

550 |

405

2800 |

|||

|

850

450 |

65

450 |

395

2700 |

|||

|

900

480 |

50

340 |

390

2700 |

|||

|

950

510 |

35

240 |

380

2600 |

|||

|

1000

540 |

20

140 |

355

2400 |

|||

Notes

- ASME B16.34

- At temperatures over 1000°F (540°C), use only if carbon content is 0.04% or higher.

- Flanged End Valve Ratings terminate at 1000°F (540°C).

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

316 Stainless Steel – ASTM A351, CF8M

DeZURIK Pressure Temperature Rating Guide

316 Stainless Steel – ASTM A351, CF8M

| Temperature (°F / °C) |

Pressure (psi / kPa) | |||

|---|---|---|---|---|

| ASME Class | ||||

| 150 | 300 | |||

|

-20 to 100

-30 to 40 |

275

1900 |

720

5000 |

||

|

200

93 |

235

1600 |

620

4300 |

||

|

300

150 |

215

1500 |

560

3900 |

||

|

400

200 |

195

1300 |

515

3600 |

||

|

500

260 |

170

1200 |

480

3300 |

||

|

600

320 |

140

970 |

450

3100 |

||

|

650

340 |

125

860 |

440

3300 |

||

|

700

370 |

110

760 |

435

3000 |

||

|

750

400 |

95

660 |

425

2900 |

||

|

800

430 |

80

550 |

420

2900 |

||

|

850

450 |

65

450 |

420

2900 |

||

|

900

480 |

50

340 |

415

2900 |

||

|

950

510 |

35

240 |

385

2700 |

||

|

1000

540 |

20

140 |

365

2500 |

||

Notes

- ASME B16.34

- Flanged End Valve Ratings terminate at 1000°F (540°C).

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

317 Stainless Steel – ASTM A351, CG8M

DeZURIK Pressure Temperature Rating Guide

317 Stainless Steel – ASTM A351, CG8M

| Temperature (°F / °C) |

Pressure (psi / kPa) | ||||

|---|---|---|---|---|---|

| ASME Class | |||||

| 150 | 300 | ||||

|

-20 to 100

-30 to 40 |

275

1900 |

720

5000 |

|||

|

200

93 |

235

1600 |

620

4300 |

|||

|

300

150 |

215

1500 |

560

3900 |

|||

|

400

200 |

195

1300 |

515

3600 |

|||

|

500

260 |

170

1200 |

480

3300 |

|||

|

600

320 |

140

970 |

450

3100 |

|||

|

650

340 |

125

860 |

440

3300 |

|||

|

700

370 |

110

760 |

435

3000 |

|||

|

750

400 |

95

660 |

425

2900 |

|||

|

800

430 |

80

550 |

420

2900 |

|||

|

850

450 |

65

450 |

420

2900 |

|||

|

900

480 |

50

340 |

415

2900 |

|||

|

950

510 |

35

240 |

385

2700 |

|||

|

1000

540 |

20

140 |

365

2500 |

|||

Notes

- ASME B16.34

- Flanged End Valve Ratings terminate at 1000°F (540°C).

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Acid-Bronze – ASTM B427 Alloy C90700

DeZURIK Pressure Temperature Rating Guide

Acid-Bronze – ASTM B427 Alloy C90700

| Temperature (°F / °C) |

Pressure (psi / kPa) | |

|---|---|---|

| ASME Class | ||

| 150 | 300 | |

|

-20 to 150

-30 to 65 |

225

1600 |

500

3400 |

|

175

79 |

220

1500 |

490

3400 |

|

200

93 |

215

1500 |

475

3300 |

|

225

110 |

210

1400 |

465

3200 |

|

250

120 |

205

1400 |

450

3100 |

|

275

140 |

200

1400 |

440

3000 |

|

300

150 |

195

1300 |

425

2900 |

|

350

180 |

180

1200 |

400

2800 |

|

400

200 |

170

1200 |

375

2600 |

|

450

230 |

160

1100 |

350

2400 |

|

500

260 |

150

1000 |

325

2200 |

|

550

290 |

140

970 |

300

2100 |

Notes

- ASME B16.24

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Alloy 20 – ASTM A351, CN7M

DeZURIK Pressure Temperature Rating Guide

Alloy 20 – ASTM A351, CN7M

| Temperature (°F / °C) |

Pressure (psi / kPa) | ||||

|---|---|---|---|---|---|

| ASME Class | |||||

| 150 | 300 | ||||

|

-20 to 100

-30 to 40 |

230

1600 |

600

4100 |

|||

|

200

93 |

200

1400 |

520

3600 |

|||

|

300

150 |

180

1200 |

465

3200 |

|||

|

400

200 |

160 1100 |

420 2900 |

|||

|

500

260 |

150 1000 |

390 2700 |

|||

|

600

320 |

140 970 |

360 2500 |

|||

Notes

- ASME B16.34

- Use solution annealed material only.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Bronze – ASTM B62, C83600

DeZURIK Pressure Temperature Rating Guide

Bronze – ASTM B62, C83600

| Temperature (°F / °C) |

Pressure (psi / kPa) | |

|---|---|---|

| ASME Class | ||

| 150 | 300 | |

|

0 to 150

15 to 65 |

225

1600 |

500

3400 |

|

175

79 |

220

1500 |

480

3300 |

|

200

93 |

210

1400 |

465

3200 |

|

225

110 |

205

1400 |

445

2800 |

|

250

120 |

195

1300 |

425

2900 |

|

275

140 |

190

1300 |

410

2800 |

|

300

150 |

180

1200 |

390

2700 |

|

350

180 |

165

1100 |

350

2400 |

|

406

210 |

150

1000 |

– |

|

450

230 |

135

930 |

280

1900 |

Notes

- ASME B16.24

- Some Codes (eg. ASME Boiler and Pressure Vessel Code, Section 1; ASME B31.1, ASME B31.5). limit the rating temperature to 406°F (210°C).

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Carbon Steel – ASTM A216, Grade WCB

DeZURIK Pressure Temperature Rating Guide

Carbon Steel – ASTM A216, Grade WCB

| Temperature (°F / °C) |

Pressure (psi / kPa) | ||||

|---|---|---|---|---|---|

| ASME Class | |||||

| 150 | 300 | ||||

|

-20 to 100

-30 to 40 |

285

2000 |

740

5100 |

|||

|

200

93 |

260

1800 |

680

4700 |

|||

|

300

150 |

230

1600 |

655

4500 |

|||

|

400

200 |

200

1400 |

635

4400 |

|||

|

500

260 |

170

1200 |

605

4100 |

|||

|

600

320 |

140

970 |

570

3800 |

|||

|

650

340 |

125

860 |

550

3700 |

|||

|

700

370 |

110

760 |

530

3700 |

|||

|

750

400 |

95

660 |

505

3500 |

|||

|

800

430 |

80

550 |

410

2800 |

|||

|

850

450 |

65

450 |

320

1900 |

|||

Notes

- ASME B16.34

- Also applies for A516-70

- Permissible, but not recommended for prolonged use above 800°F (450°C) A216WCB and A516-70.

- Upon prolonged exposure to temperatures above 800°F (450°C), the carbide phase of steel may be converted to graphite.

- Not to be used over 850°F (450°C) A516-70.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Cast Iron – ASTM A126, Class B

DeZURIK Pressure Temperature Rating Guide

Cast Iron – ASTM A126, Class B

| Temperature (°F / °C) |

Pressure (psi / kPa) | |||||

|---|---|---|---|---|---|---|

| ASME Class 125 | ASME Class 250 | |||||

| 1″-12″ | 14″-24″ | 30″-48″ | 1″-12″ | 14″-24″ | 30″-48″ | |

|

-20 to 150

-30 to 65 |

200

1400 |

150

1000 |

150

1000 |

500

3400 |

300

2100 |

300

2100 |

|

200

93 |

190

1300 |

135

930 |

115

790 |

460

3200 |

280

1900 |

250

1700 |

|

225

110 |

180

1200 |

130

900 |

100

690 |

440

3000 |

270

1900 |

225

1600 |

|

250

120 |

175

1200 |

125

860 |

85

590 |

415

2900 |

260

1800 |

200

1400 |

|

275

140 |

170

1200 |

120

830 |

65

450 |

395

2700 |

250

1700 |

175

1200 |

|

300

150 |

165

1100 |

110

760 |

50

340 |

375

2600 |

240

1700 |

150

1000 |

|

325

160 |

155

1100 |

105

720 |

– |

355

2400 |

230

1600 |

125

860 |

|

353

180 |

150

1000 |

100 690 |

– |

335

2300 |

220

1500 |

100

690 |

|

375

190 |

145

1000 |

– | – |

315

2200 |

210

1400 |

– |

|

406

210 |

140

970 |

– | – |

290

2000 |

200

1400 |

– |

|

425

220 |

130

900 |

– | – |

270

1900 |

– | – |

|

450

230 |

125

860 |

– | – |

250

1700 |

– | – |

Notes:

- ASME B16.1

- 353°F (max.) reflects the temperature of saturated steam at 125 psi.

- 406°F (max.) reflects the temperature of saturated steam at 250 psi.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Ductile Iron – ASTM A536, Grade 65-45-12

DeZURIK Pressure Temperature Rating Guide

Ductile Iron – ASTM A536, Grade 65-45-12

| Temperature (°F / °C) |

Pressure (psi / kPa) | |

|---|---|---|

| ASME Class 150 | ASME Class 300 | |

|

-20 to 100

-30 to 40 |

250

1720 |

640

4410 |

|

200

90 |

235

1620 |

600

4135 |

|

300

150 |

215

1480 |

565

3895 |

|

400

200 * |

200

1380 |

525

3620 |

|

500

260 * |

170

1170 |

495

3410 |

|

600

315 * |

140

965 |

465

3205 |

|

650

345 * |

125

860 |

450

3100 |

Notes

- ASME B16.42

- *ASTM A395, Grade 60-40-18 above 450°F (230°C)

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Hastelloy C – ASTM A494, CW-12MW

DeZURIK Pressure Temperature Rating Guide

Hastelloy C – ASTM A494, CW-12MW

| Temperature (°F / °C) |

Pressure (psi / kPa) | ||||

|---|---|---|---|---|---|

| ASME Class | |||||

| 150 | 300 | ||||

|

-20 to 100

-30 to 40 |

230

1600 |

600

4100 |

|||

|

200

93 |

210

1400 |

550

3800 |

|||

|

300

150 |

200

1400 |

520

3600 |

|||

|

400

200 |

190

1300 |

490

3400 |

|||

|

500

260 |

170

1200 |

465

3200 |

|||

|

600

320 |

140

970 |

440

3000 |

|||

|

650

340 |

125

860 |

430

3000 |

|||

|

700

370 |

110

760 |

420

1900 |

|||

|

750

400 |

95

660 |

410

2800 |

|||

|

800

430 |

80

550 |

400

2800 |

|||

|

850

450 |

65

450 |

395

2700 |

|||

|

900

480 |

50

340 |

385

2700 |

|||

|

950

510 |

35

240 |

380

2600 |

|||

|

1000

540 |

20

140 |

365

2500 |

|||

Notes

- ASME B16.34

- Flanged End Valve Ratings terminate at 1000°F (540°C).

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Monel – ASTM A494, M-35-1

DeZURIK Pressure Temperature Rating Guide

Monel – ASTM A494, M-35-1

| Temperature (°F / °C) |

Pressure (psi / kPa) | ||||

|---|---|---|---|---|---|

| ASME Class | |||||

| 150 | 300 | ||||

|

-20 to 100

-30 to 40 |

230

1600 |

600

4100 |

|||

|

200

93 |

200

1400 |

525

3600 |

|||

|

300

150 |

190

1300 |

490

3400 |

|||

|

400

200 |

180

1300 |

475

3300 |

|||

|

500

260 |

170

1200 |

475

3300 |

|||

|

600

320 |

140

970 |

475

3300 |

|||

|

650

340 |

125

860 |

475

3300 |

|||

|

700

370 |

110

760 |

475

3300 |

|||

|

750

400 |

95

660 |

470

3200 |

|||

|

800

430 |

80

550 |

460

3200 |

|||

|

850

450 |

65

450 |

340

2300 |

|||

|

900

480 |

50

340 |

245

1700 |

|||

Notes

- ASME B16.34

- Use annealed material only.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Metal Material Data – Material Characteristics

17-4PH Stainless Steel

DeZURIK Material Characteristics Guide

17-4PH Stainless Steel

17-4PH stainless steel is a martensitic precipitation or age hardening alloy offering high strength and hardness along with excellent corrosion resistance. In general, the corrosion resistance is similar to that of 304 stainless steel. In addition, 17-4PH retains its corrosion resistance to temperatures about 50°F (10°C) less than the aging temperature. It also has excellent resistance to stress-corrosion cracking when hardened at 1025°F (552°C) or above. Hardening is achieved at temperatures from 900°F (482°C) to 1150°F (621°C). It may be machined in the annealed condition but it is not used until hardened.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

440C Stainless Steel

DeZURIK Material Characteristics Guide

440C Stainless Steel

440C stainless steel is a high carbon martensitic chromium steel alloy designed to provide stainless properties with maximum hardness. It is generally used in the hardened and tempered condition. When fully heat treated 440C attains the highest hardness of any stainless steel, about Rockwell C 60. It is used primarily for parts subjected to high wear applications. 440C resists normal domestic and mild industrial environments, including many petroleum products and organic materials.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Aluminum ASTM B26, Alloy 356 & Alloy 713

DeZURIK Material Characteristics Guide

Aluminum ASTM B26, Alloy 356 & Alloy 713

Corrosion resistance of aluminum is dependent on the formation of a protective oxide film on the surface of the metal. This film is stable in aqueous media when the pH range is between 4.5 and 8.5. Corrosion resistance is dependent on the media that forms the film. Galvanic corrosion is a potential problem when aluminum is used in complex structures. Aluminum is anodic to most of the common materials such as iron , steel, stainless, titanium and nickel alloys.

| Mechanical Properties | Alloy 356 | Alloy 713 |

|---|---|---|

| Tensile Strength | 30,000 psi min. | 32,000 psi min. |

| Yield Strength | 20,000 psi min. | 22,000 psi min. |

| Elongation (in.) | 3% min. | 3% min. |

| Hardness,Brinell | 70 BHN | 75 BHN |

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

2205 Duplex Stainless Steel ASTM A995, Type CD3MN

DeZURIK Material Characteristics Guide

2205 Duplex Stainless Steel ASTM A995, Type CD3MN

Duplex Stainless steel is a grade that in the annealed state is composed of about equal parts of ferrite and austenite. Duplex stainless offer several advantages over austenitic grades. Duplex stainless grades are highly resistant to chloride stress corrosion cracking, have excellent pitting/crevice corrosion resistance and exhibit about twice the mechanical properties of austenitic stainless steels.

MECHANICAL PROPERTIES:

| Mechanical Properties | Duplex SST |

|---|---|

| Tensile Strength | 100,000 psi minimum |

| Yield Strength | 70,000 psi minimum |

| Elongation (in.) | 25% minimum |

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

GrafoilR

DeZURIK Material Characteristics Guide

Grafoil®

Grafoil® Gaskets and packing are all-graphite products containing no resin binders or organic fillers. Their outstanding resistance to corrosion, even at high temperatures, and their ability to retain compressibility at all temperatures, allows them to be recommended for service in many organic and inorganic applications.

Grafoil® is a registered trademark of Union Carbide Company.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Cobalt-Chromium Alloys (Stellite®)

DeZURIK Material Characteristics Guide

Cobalt-Chromium Alloys (Stellite®)

Stellite® is a registered trademark name for a series of cobalt based alloys with outstanding wear resistance. Cobalt-Chromium Alloys are available in most forms: wrought, cast, and powder metal parts. The most common use for Cobalt-Chromium Alloys is for hard facing on shafts, valve seats, and other high wear surfaces. This is done either by welding or spraying the alloy on a base metal surface. The most commonly used alloys are Stellite® 6, 4 and 12. Alloy 6 is the most frequently used because it is an excellent compromise of a hard wear resistant material with excellent resistance to corrosion, high temperatures, and shock loads. Alloys 4 and 12 are somewhat harder, but are less resistant to high temperatures and shock loads.

Stellite® is a registered trademark of Deloro Stellite, Holdings Corporation.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Tiodizing

DeZURIK Material Characteristics Guide

Tiodizing

Tiodizing is a coating deposited on titanium or titanium alloys by an electrolytic process using an alkaline bath. The primary reasons for using this coating are to eliminate the severe galling and seizing tendencies of uncoated titanium and to improve the wear resistance of the metal surface. Tiodizing does not alter the corrosion resistance of the base titanium or titanium alloy. The only corrosion resistance improvement is to prevent surface corrosion from hypergolic fuels, such as hydrazine and nitrogen tetroxide.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Titanium ASTM B367, Alloy C-2

DeZURIK Material Characteristics Guide

Titanium ASTM B367, Alloy C-2

As aluminum and stainless steel, titanium is dependent on an oxide film for its corrosion resistance. Titanium performs best in oxidizing media such as nitric acid. Titanium also has excellent corrosion properties in sea water, wet chlorine and organic chlorides.

MECHANICAL PROPERTIES:

| Mechanical Properties | Titanium |

|---|---|

| Tensile Strength | 50,000 psi minimum |

| Yield Strength | 40,000 psi minimum |

| Elongation (in.) | 15% minimum |

| Hardness,Brinell | 210 BHN maximum |

| Hardness,Rockwell | 96 B maximum |

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.

Tungsten Carbide

DeZURIK Material Characteristics Guide

Tungsten Carbide

Tungsten Carbide may be used as sintered powder metal parts or as a coating sprayed on the surface of a part. Carbides consist of finely divided grains held together with a binder, such as cobalt or nickel. Since tungsten is inert, the corrosion resistance of the tungsten carbide is dependent upon the binder used. Nickel is commonly used as the binder to provide optimum corrosion resistance. The hardness of a tungsten carbide surface is about Rockwell A90, which is similar to a hardness of Rockwell C76. The surface of tungsten carbide can be ground to a 15 to 20 micro inch surface finish and polished even smoother if required. The combination of hardness and smoothness give an exceptionally wear resistant surface. Tungsten carbide can be used effectively to 1000°F (538°C) in an oxidizing atmosphere and up to 1600°F (871°C) in a non-oxidizing atmosphere. It has been determined that it is also an excellent material at cryogenic temperatures.

No representation, warranty or guarantee, express or implied, is made by this selection guide due to the complexity and almost infinite variations of mixtures, concentrations, temperature and flow conditions possible in actual service.