Hilton Material Handling Knife Gate Valves (H-290)

Design Features:

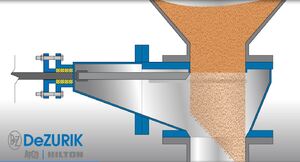

Fabricated Material Handling Knife Gate Valves are specifically designed to be used on dry bulk materials where the valve is installed horizontally in a vertical pipe. A displacement pocket is provided which enables the valve to close through a standing column of packed material. Bonneted or bonnetless configuration. Available with round, square, rectangular or combination port with a round port on one side and a square or rectangular port on the other side, eliminating the need for a transition piece.

Click on the animation to see how the Hilton Material Handling Knife Gate Valve pushes dry material into a displacement pocket, allowing the valve to fully close on a standing column. The animation also shows how the gate guide maintains gate alignment throughout the stroke.

Material Handling Knife Gate Valves (H-290) Specifications

SIZE RANGE:

Through 48"

TEMPERATURE RANGE:

up to 2000°F

SEATING:

Metal or Resilient with options for removable seat

MATERIALS:

Valves are available in solid, wetted parts or trim construction in any weldable alloy, including Stainless Steel, Hastelloy, Inconel, Monel and Titanium.

ABRASIVE SERVICE:

Optional abrasion and corrosion resistant designs with hard facing available in Stellite, Tungsten Carbide, Pulse Fusion.

VALVE STYLE:

H-290, Bonnetless Valve

H-290-B, Bonneted Valve

Bulletins (English)

- Hilton H-290 Bonnetless Tapered Body Knife Gate Valve, 4-24” Design Details H-290

- Hilton H-290, Bonneted Tapered Body Knife Gate Valve, 4-24” Design Details H-290-B

- Hilton Fabricated and Custom Valves 10.00-11

- Valves for Polymer Handling in Petrochemical Manufacturing 65.00-3

Application Solutions (English)

Animations