News

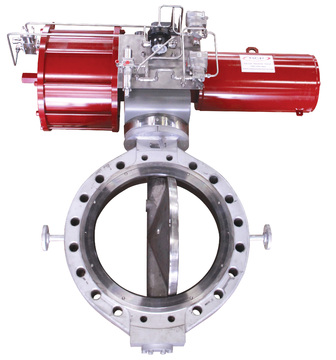

DeZURIK High Performance Butterfly Valves Prevent Build-up In Fly Ash Service

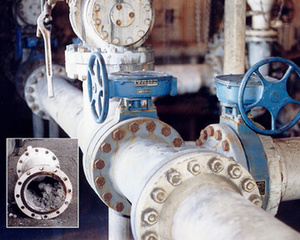

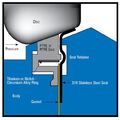

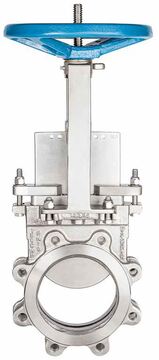

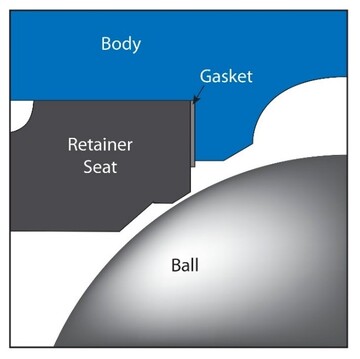

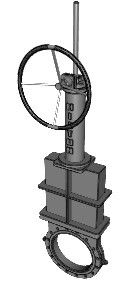

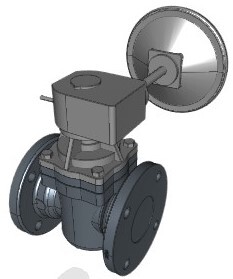

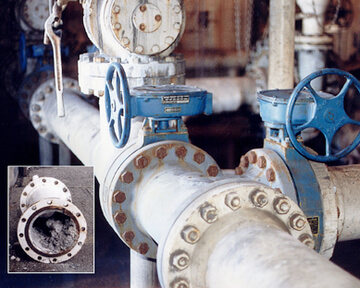

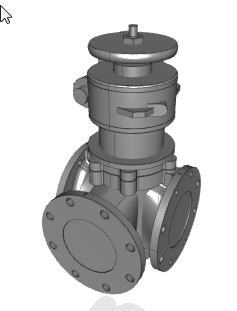

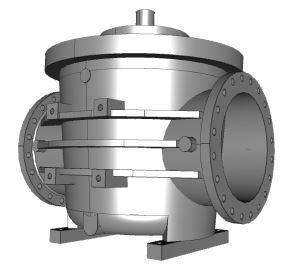

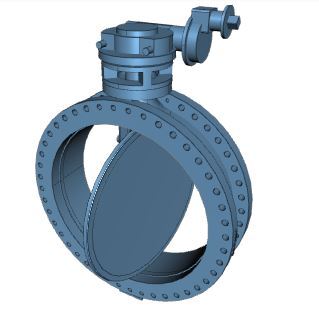

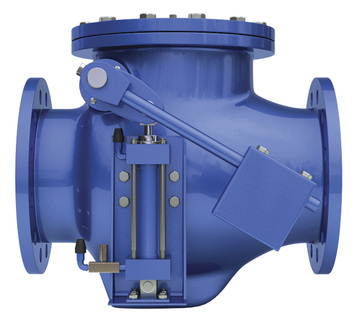

The double seat design of DeZURIK Dual Seat BHP High Performance Butterfly Valves enables them to withstand the severe abrasion of high pressure, fly ash slurry service in a power plant. Damage from abrasion is prevented by standard construction features including the 316 stainless steel disc with heat hardened nickel coating and the secondary metal seat. The valves were installed with flow direction into the seat side, thus allowing the metal seat to protect the primary PTFE seat from abrasion.

After one year of maintenance-free operation in this service, eight 10" Dual Seat High Performance Valves were examined during the annual cleanout. Upon inspection, no evidence of wear or damage was apparent, and the valves remained free of calcium/slurry buildup. The plant had previously used lubricated plug valves in this service, but found they required frequent maintenance because the build-up of fly ash slurry prevented the plug valves from sealing or operating. The plant also found that replacement with the same type plug valves would cost three times more than the DeZURIK BHP valves.

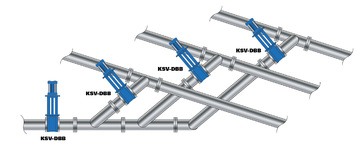

Careful scrutiny of the process conditions led to the selection of the DeZURIK BHP Dual Seat High Performance Butterfly Valve. Fly ash slurry from the plant's precipitators is pumped at a rate of 700 to 800 gpm at 275 psig a distance of 2.5 miles from the pump house to the settling pond. The valves, installed in the pump house, were required for on-off service. Composition of the slurry is 90% water, 8% fly ash, 1.5% sludge and 1,000 ppm calcinated lime.

Application Solution #101 DeZURIK BHP High Performance Butterfly Valves For Fly Ash Slurry Service