News

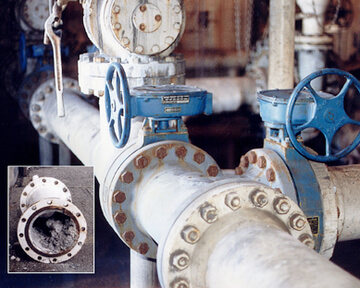

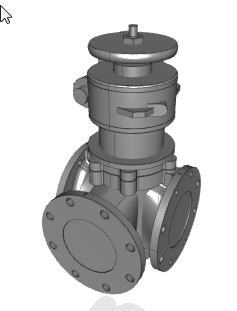

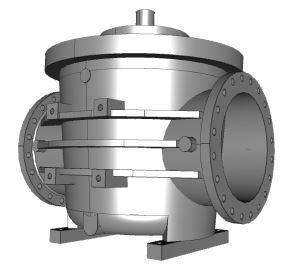

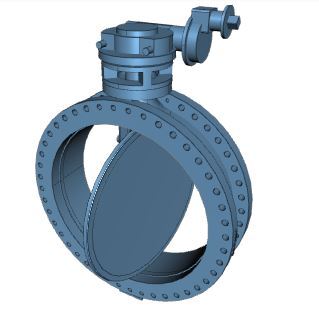

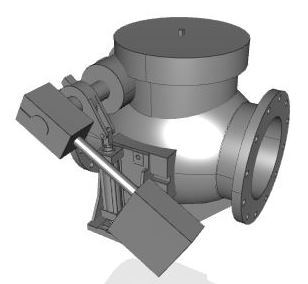

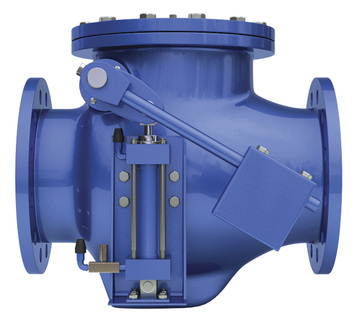

Slurry Knife Gate Valves Deliver Drip-Tight Shutoff in Abrasive Applications

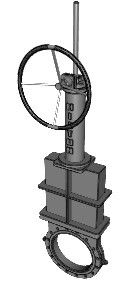

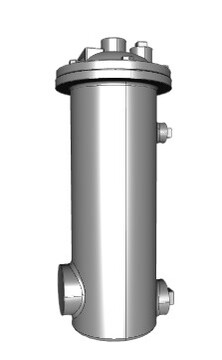

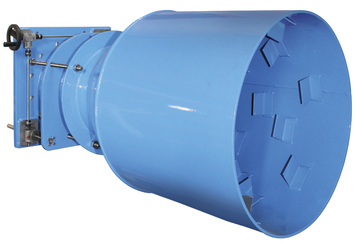

DeZURIK KSL Slurry Knife Gate Valves, designed for on-off isolation service, are ideally suited for applications consisting of abrasive, high solids content, wet or dry media in the mining, power and aggregate industries.

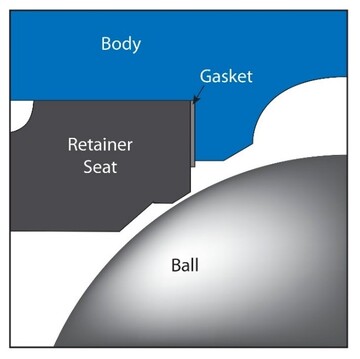

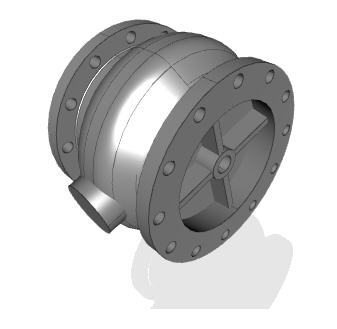

Available in two styles, Long Body Design (KSL-LA) and Short Body Design (KSL-SD), DeZURIK Slurry Knife Gate Valves feature sleeves of natural rubber, EPDM or other elastomers that are compressed by sleeve retainers, allowing the valve to provide drip-tight shutoff and exceptional service life in abrasive and erosive applications.

Features of Slurry Knife Gate Valves include:

• Bi-directional, drip-tight shutoff to full pressure rating.

• Field replaceable sleeves with encapsulated supporting ring.

• Full port reduces turbulence and pressure drop across the valve.

• Sleeve compression eliminates cavity where solids can collect.

• Sleeve design eliminates the requirement for flange gaskets.

• Gate fully retracts out of the flow path in the open position.

• Optional open and closed position lock-outs.

DeZURIK Slurry Knife Gate Valves are available in sizes 2-24" (50-600mm) with larger sizes available on application. Temperature ratings to 177°F (81°C) as standard, and up to 300°F (150°C) with high temperature optional seat materials. Depending on the application requirements, the cast body is available in Ductile Iron, Carbon Steel and various Stainless Steel or higher alloy materials.

Detailed information for each Slurry Knife Gate Valve style, including specifications and instruction manuals, can be found on the Slurry Knife Gate Valve product pages.